CIP Chemical Cleaning Technical Guidelines for Reverse Osmosis Systems

CIP Chemical Cleaning Technical Guidelines for Reverse Osmosis Systems

The main reason for chemical cleaning (chemical cleaning or IP, i.e., in-place cleaning) of reverse osmosis membrane systems is to restore the performance of the membrane, prolong the service life of the membrane, and ensure the efficient and stable operation of the system.Conventional physical cleaning (e.g., low-pressure washing, air scrubbing) can only remove loose contaminants from the membrane surface, while chemical cleaning can more thoroughly remove stubborn contaminants (e.g., scaling, biofilm, etc.) through the dissolution, dispersion, oxidation or sterilization of chemical reagents

Table of Contents

I. Cleaning Trigger Criteria

- Permeate flow decline: Standardized flow reduction >15% (vs. initial value)

- Salt rejection deterioration: System salt rejection drop >10% (e.g., 98% → 88%)

- Pressure difference increase: Inter-stage ΔP increase >15% (e.g., 0.5MPa → 0.58MPa)

- Visible contamination: Colored deposits on membrane surface (biofilm/iron scale)

II. Pre-Cleaning Preparation

1. System Inspection

- Verify pressure gauge/flow meter accuracy (<±2% error)

- Check cleaning pump capacity (1.5× system design flow rate)

- Ensure cleaning tank volume >1.2× system water volume

2. Safety Precautions

- PPE: Acid/alkali-resistant clothing, face shield, chemical-resistant gloves

- Set up pH monitoring in restricted zones

3. Chemical Formulation

| Cleaning Phase | Chemical Formula | Concentration | Temperature |

|---|---|---|---|

| Alkaline Cleaning | NaOH + EDTA-4Na + Surfactant | 0.1%-0.5% | 35-40℃ |

| Acid Cleaning | Citric Acid/HCl + Corrosion Inhibitor | 1%-2% | 25-30℃ |

| Disinfection | Peracetic Acid/Sodium Bisulfite | 0.5%-1% | Ambient |

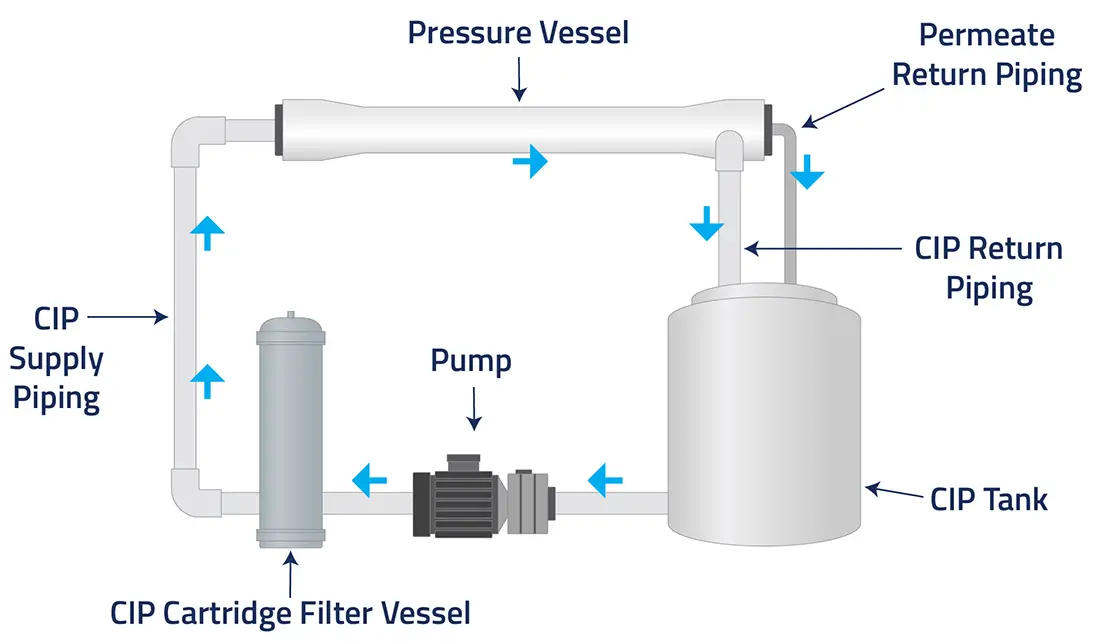

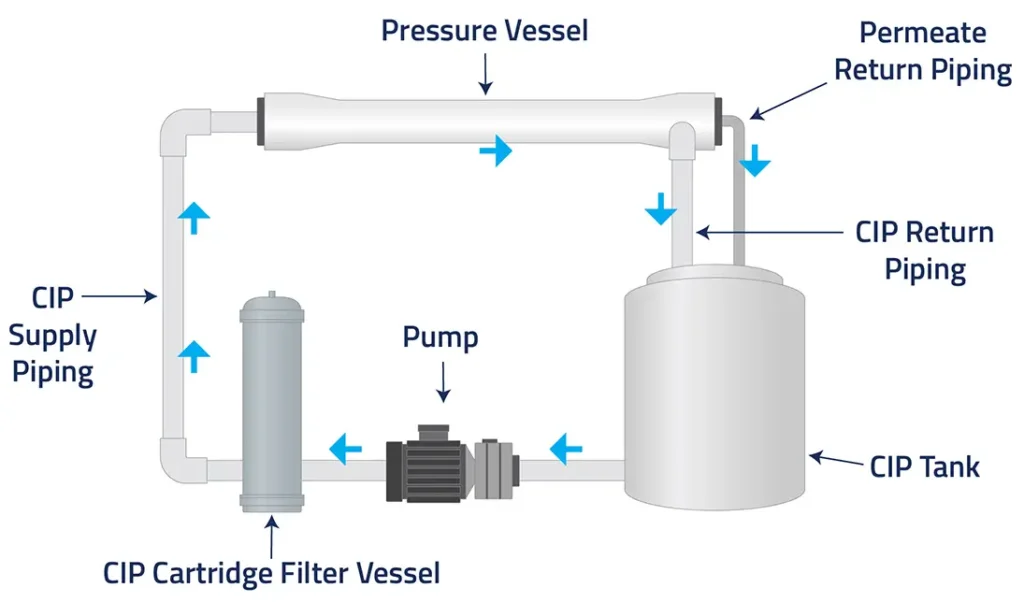

4. System Isolation

- Close permeate valve, fully open concentrate valve

- Keep membrane housing vent valves open

- Disconnect from pretreatment system

III. Step-by-Step Cleaning Procedure

Step 1: Low-Pressure Flushing

- Flush system with RO permeate for 30 minutes

- Flow rate: 50% of design flow

- Objective: Remove loose contaminants

Step 2: Alkaline Cleaning (Organic/Biofilm Removal)

- Circulation:

- Flow rate: 8-10m³/h (for 8-inch membrane)

- Duration: 60-90 minutes

- Transmembrane pressure: <0.2MPa

- Soaking:

- Turn off pump and soak for 4-6 hours

- Maintain solution temperature ≥30℃

- Drainage:

- Check effluent turbidity (NTU <5)

Step 3: Acid Cleaning (Inorganic Scale Removal)

- Circulation:

- Flow rate: 6-8m³/h (prevent CaCO3 re-precipitation)

- Duration: 45-60 minutes

- Monitor pH (2.5-3.5)

- Endpoint:

- Stop when conductivity change <5%/hour

Step 4: Disinfection

- For severe biofouling:

- 0.1% peracetic acid circulation for 30 minutes

- OR 1% sodium bisulfite soak for 2 hours

Step 5: Final Flushing

- Alternate forward/reverse flushing with RO permeate

- Continue until effluent pH 6.5-7.5

- Conductivity returns to baseline ±10%

IV. Post-Cleaning Evaluation

- Performance recovery:

- Permeate flow recovery ≥95%

- Salt rejection improvement ≥3%

- Membrane autopsy (if needed):

- Contaminant weight: <50mg/cm²

- SEM analysis of membrane pores

V. Targeted Solutions for Specific Fouling

| Fouling Type | Symptoms | Recommended Solution |

|---|---|---|

| Organic Fouling | Rapid ΔP rise, stable conductivity | Alkaline cleaner (pH11-12) + 50℃ heating |

| Inorganic Scaling | Sudden flow drop, salt rejection decline | 2% citric acid + NH3 (pH4) + 40℃ circulation |

| Biofouling | Odor, slimy deposits | Alternate 1% peracetic acid and 0.1% NaOH |

| Colloidal Fouling | SDI >5, gradual ΔP rise | 0.025% SDBS + EDTA composite cleaning |

VI. Safety Protocols

- Chemical compatibility:

- Avoid mixing oxidizers (e.g., NaClO) with acids

- Flush alkaline residues before acid cleaning

- Waste treatment:

- Neutralize pH to 6-9

- Precipitate EDTA with FeCl3 (1:1 molar ratio)

- Membrane protection:

- Set temperature alarm at 45℃

- Limit Cl- concentration <1000ppm during acid cleaning

Expected Outcomes:

- Flux recovery >90%

- Extended membrane lifespan (12-18 months)

- 8-12% energy consumption reduction

Hi, I am the author of this article and I have been working in this field for more than 8 years. If you want to know about water treatment related knowledge and products, please feel free to ask me any questions.

Connect with me